CHOPPERDAVES

SO CAL VAPOR HONE

Vapor Blasting our way to the best surface finish possible!

Since 2005, Chopperdaves has provided quality services to clients by offering the professional care they deserve.

Get in touch today to learn more about our Vapor Blasting Service.

ALL ABOUT CHOPPERDAVES

SO CAL VAPOR HONE

I am a Harley Davidson mechanic who has spent the past 30 years building high end custom motorcycles and after years of doing restoration work, I have come to the conclusion that Vapor Hone Blasting technology is the most groundbreaking innovation in years.

We take your aluminum, brass, bronze, stainless, and ferrous metals, giving them a restored look that in many cases is better than original. With the additional fact that it creates a more durable finish, it's the perfect way to bring your parts back to a stunning condition.

2 to 3 day turn around for most jobs.

Contact us to get a quote or if you have any further questions.

WHY VAPOR HONE BLASTING IS FAR SUPERIOR.

Chopperdaves So Cal Vapor Hone is dedicated to providing high quality services to the Southern California area.

Take a look below to get an idea as to why this process is what you are looking for for your next project.

THE VAPOR HONE ADVANTAGE

The first of many advantages of wet blasting is it cleans by flow of water and abrasive running across the part surface not by sheer force and impact like in conventional dry blasting operations.

Water acts as a lubricant or barrier between the abrasive media & components surface protecting the substrate from erosion and distortion normally found in dry blasting environments.

Wet blasting can provide a slight surface peening depending on the abrasive media used helping make the substrate harder and more stain resistant ideal in restoration applications.

One of the clear advantages in the wet slurry process is the fact that no media is impregnated into a softer substrate like aluminum, brass and bronze.

Within wet slurry environments the water and moisture traps and reduces the harmful dust particles that have been found to have negative health effects when inhaled.

Since the water cushions the abrasive media being used this greatly extends abrasive life normally around 8-10 times longer than a dry blasting process.

Closed loop machinery that recycles the abrasive and water decreasing operating cost.

No heat warping with thin parts with the impact protection of the water as a barrier. When part distortion and close tolerances are of concern wet blasting is a great option for processing and testing your parts.

Eliminates the need to use nasty chemicals which are found in rebuild shops around the world. These chemicals come with costly disposal fees and hazardous work environments.

Leaves a very attractive satin finish on many different substrates like stainless steel, aluminum, brass.

Provides an excellent lightly etched surface for bonding within the specialty coating markets. While helping retain part form and function.

Provides an excellent surface for plating by cleaning the topography of the surface. With the flushing action of combined water and abrasive allows optimal surfacecleanliness and preparation for final plating operations.

2 to 3 day turn around for most jobs.

Contact us to get a quote or if you have any questions.

2020 © Copyright Vapor Honing Technologies

GALLERY

Below are numerous examples of the striking differences before and after Vapor Blasting.

Click on a picture to see it full size.

Used 45" Piston before blasting

That same piston after being Vapor Blasted

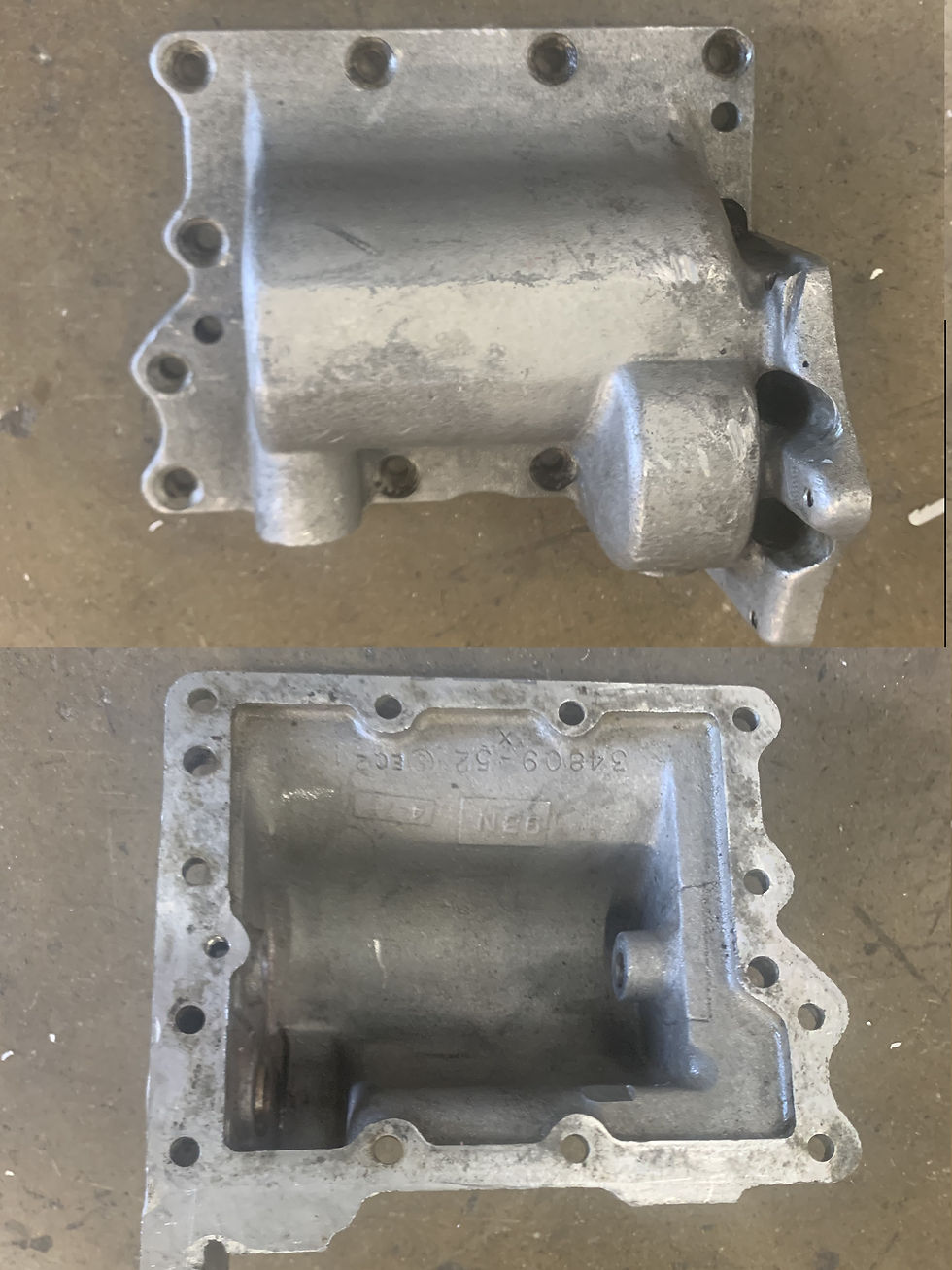

HD Transmission ratchet lid before

HD Transmission ratchet lid after Vapor Blasting!

Old and crusty!

Better than new!!!

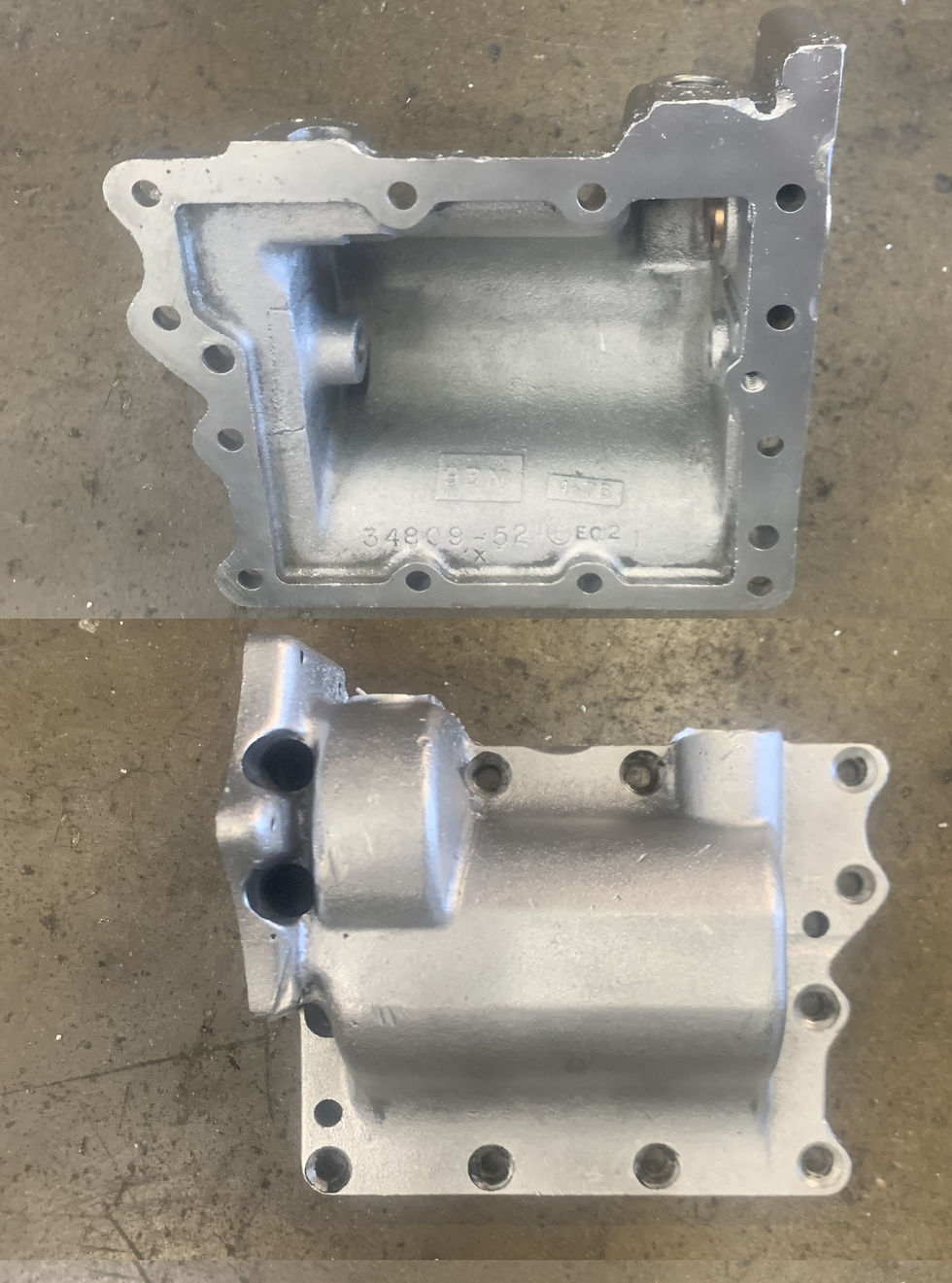

This case was dry bead blasted about a year ago.

After a freshening up in the vapor hone.

Typical old case...

All new!

Steel Clutch plate with glazing

No more glazing.

Normal wear and rust inside.

Clean!

1953 HD Cast Cam Cover

This 1953 cover is super rare, one year only item, thaty now looks beautiful and it's ready to be run.

Before and after blasting, leaving a killer satin finish

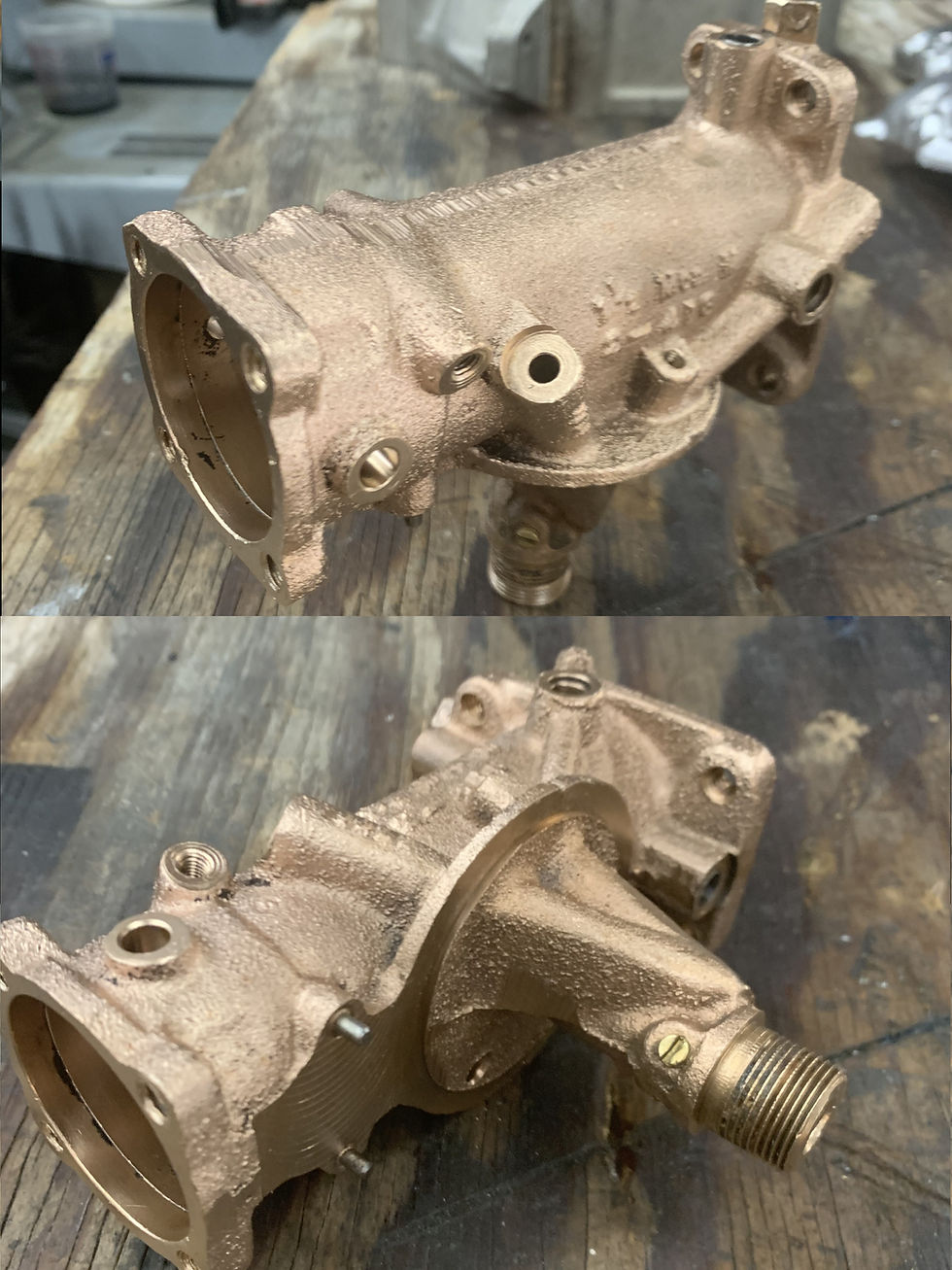

Old Offy carb adapter before blasting

After blasting, acan be proud to run this on your hot rod.

i was making a filler cap for my Born Free build and needed to use this ugly collet...

After i blasted it! So much better.

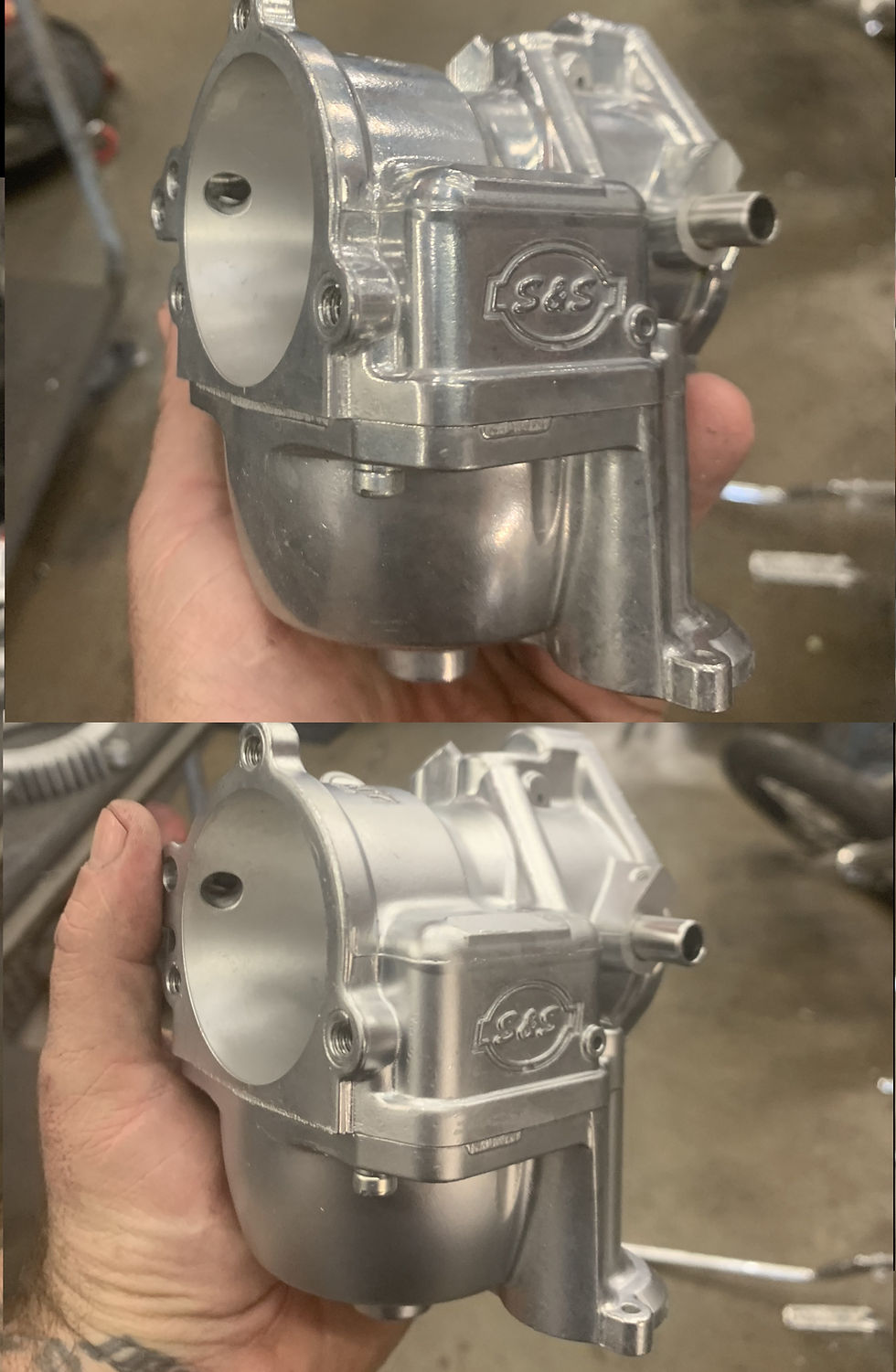

Before and after

since i blasted an S&S carb...

What a difference, the aluminum, steel and plastic!

Normal 4 speed kicker cover before

and after blasting

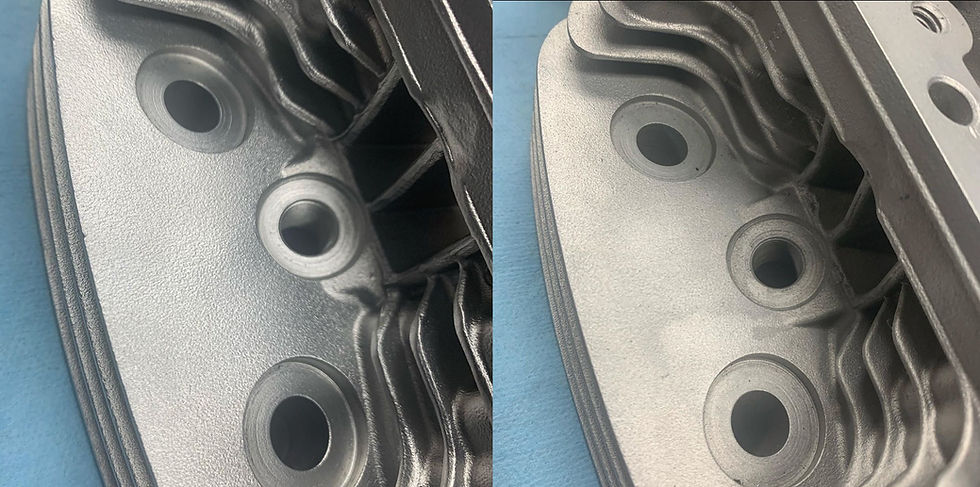

left head is vapor blasted, right head is conventional glass bead

left head is vapor blasted, right head is conventional glass bead

left head is vapor blasted, right head is conventional glass bead

left head is vapor blasted, right head is conventional glass bead

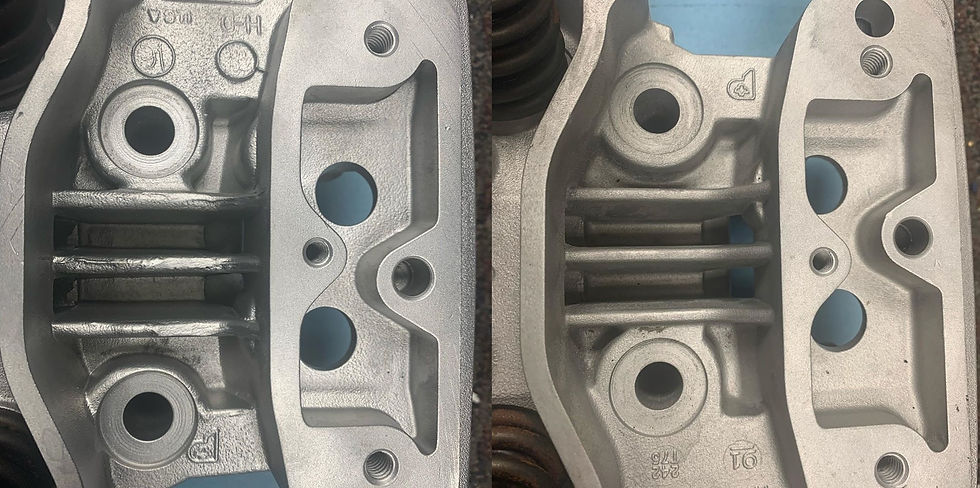

left side vapor blasted, right side conventional bead blast

right side (In the pic, its actually the left case) is vapor blasted the other conventional bead blast

VAPOR HONE APPLICATIONS

What can we blast?

AUTOMOTIVE RESTORATION

Do you want your engine parts to look immaculate before you are ready to assemble? We blast everything... crankshafts, camshafts, pump housings, valve covers, intake manifolds, carburetors, and all the small bits.

MOTORCYCLE RESTORATION

Nothing looks better than perfectly blasted aluminum engine cases, heads and cylinders. Not only will your wheel hubs, brake backing plates, risers and triple trees look better than brand new but they will have a far more durable finish.

TOOLING REFINISHING

Do you have or do you run a machine shop? Your tooling can get rusty and dirty after years of use. Your tapers can get gummed up and not seat properly. We can refinish them to a pristine condition so you can keep manufacturing parts without worrying about your tooling.

FIREARM DEEP CLEANING

If you are an avid shooter or doing firearm restoration and want your surfaces returned to tip top condition, we can do it for you. Vapor Hone Blasting can remove gun bluing and all the grime that can develop in a firearm.

AVIATION

Whether it is a new build or vintage aircraft hardware, we can refinish and restore your engine parts, landing gear or control arms.

VINTAGE HOME FIXTURES

Are you refurbishing an old house or vintage appliances?

We can help return your fittings, knobs, hardware as well as light fixtures and wall mounts to mint condition.

HIT US UP!

Hours:

Tuesday - Friday 10:00 to 5:00

Monday, Saturday and afterhours by Appt.

12020 Centralia Unit H

Hawaiian Gardens CA 90716

562 844 9103